Why PVC Is a Durable Choice for Custom Patches

in Custom Patches, Patch Materials, PVCThe durability of PVC as a material for custom patches is increasingly recognized in various applications, particularly where resilience is paramount. Unlike traditional options such as embroidered or woven patches, PVC offers superior resistance to moisture, chemicals, and environmental stressors, ensuring a longer lifespan. This material not only maintains its vibrancy but also withstands the rigors of high-stress environments. As we explore the comparative advantages of PVC over other patch types, the implications for industries that demand durability become clear, prompting further examination of its unique benefits.

5 Big Reason of Durability

- PVC patches are highly durable due to their exceptional tensile strength, ensuring they maintain integrity under stress.

- They resist moisture, chemicals, and UV exposure, making them ideal for outdoor and industrial applications.

- Unlike embroidered and woven patches, PVC does not fray or fade, maintaining vibrancy over time.

- The flexible design allows for intricate detailing without compromising durability, offering superior visual appeal.

- PVC’s impact resistance can be enhanced with varying thicknesses, providing versatility in different environments.

Unique Features of Pvc Patches

Material: When considering materials for custom patches, many find that polyvinyl chloride (PVC) stands out as an exceptionally durable option. This synthetic polymer is renowned for its robustness and resistance to various environmental factors. PVC exhibits high tensile strength, ensuring that patches maintain their structural integrity even under stress, making them suitable for heavy-duty applications.

Resistance: One key characteristic of PVC is its unparalleled resistance to moisture and chemicals. This property renders it highly effective in outdoor settings where exposure to rain, sunlight, and pollutants is a concern. Additionally, PVC is resistant to abrasion, which is critical for patches subjected to friction or wear, enhancing their longevity.

Flexibility: The material’s flexibility allows for intricate designs without compromising durability. The capacity to withstand extreme temperatures, both hot and cold, further adds to its versatility. PVC patches can be easily cleaned and maintained, preserving their aesthetic appeal over time.

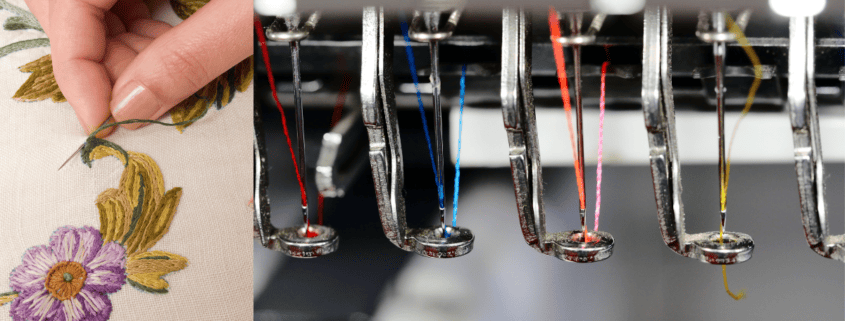

Pvc Vs. Embroidery Patches

When comparing the durability of PVC patches to embroidered, several factors must be considered. PVC patches exhibit superior resistance to wear, fading, and environmental elements, which can greatly enhance their longevity.

In contrast, embroidered patches are composed of threads stitched onto a fabric backing. While they can exhibit a certain degree of durability, they are more vulnerable to abrasion and can suffer from thread unraveling, especially when exposed to harsh conditions.

Moreover, PVC patches can withstand extreme temperatures without losing shape or detail, whereas embroidered patches may become stiff or misshapen under similar conditions.

The rigidity of PVC allows for precise detailing that is often difficult to achieve with thread-based designs.

Overall, for applications requiring prolonged exposure to challenging environments, PVC patches demonstrate a clear advantage over their embroidered counterparts with regard to durability.

Pvc Patches Vs. Chenille

Chenille patches, made from woven cotton twill, felt fabric and acrylic yarn threads. They typically featuring a looped texture, have inherent vulnerabilities. The fibers of felt can fray or fade when exposed to moisture and sunlight, compromising their aesthetic and functional durability.

Additionally, chenille patches are more susceptible to wear and tear in high-friction environments, such as on uniforms or bags subjected to constant movement.

Comparing to PVC patches, Pvc can be produced with varying thicknesses, allowing for enhanced impact resistance. This adaptability is not as easily achievable with chenille, which is limited by its fabric construction.

Pvc Patches Vs. Woven

Woven patches, typically made from threads of polyester or cotton, are more fragile to tear compared to sturdy rubber made pvc patches. While they offer a traditional aesthetic and are breathable, their fibers can fray over time, particularly in high-friction environments.

As compared, PVC patches are often designed with a raised surface that can better withstand impacts, whereas woven patches may lack this structural resilience. To sum up, when considering durability.

Pvc Patches Vs. Printed

Dye-subli or sticker printed patches typically utilize base material with inks and dyes, which can be susceptible to fading, cracking, and peeling over time. The longevity of printed patches is often compromised by exposure to the elements, washing, and mechanical abrasion. While high-quality inks can improve durability, they generally do not match the inherent robustness of PVC.

When it comes to Rubber made, PVC soft rubber patches are not only resistant to physical wear but are also impervious to chemicals and biological agents, further enhancing their lifespan. This makes them suitable for applications in industries where durability is paramount, such as military, outdoor, and industrial settings.

Frequently Asked Questions

Can PVC Patches Be Customized in Different Shapes and Sizes?

Yes, PVC patches can be customized into various shapes and sizes. This versatility allows for intricate designs and unique branding opportunities.

How Do PVC Patches Compare in Cost to Embroidered Patches?

PVC patches generally have a higher initial cost compared to embroidered patches due to material and production techniques. However, their durability and lower maintenance requirements may offer better long-term value, depending on usage context.

Are PVC Patches Safe for Children’s Clothing?

PVC patches are generally safe for children’s clothing, provided they meet safety standards. Patches Mania offers special material treatment for healthy production and certified from authentic hospitals.

Can PVC Patches Be Machine Washed Without Damage?

PVC patches can generally withstand machine washing; however, it is advisable to use a gentle cycle and cold water to minimize potential wear.

Custom Patches Mania

Custom Patches Mania Custom Patches Mania

Custom Patches Mania

Custom Patches Mania

Custom Patches Mania

Custom Patches Mania

Custom Patches Mania Custom Patches Mania

Custom Patches Mania Custom Patches Mania

Custom Patches Mania