Customizing Player Number Patches for Sports Team

in Custom Patches, Player Numbers, Sports PatchesCustomizing player number patches for sports teams need key things such as team requirements and selecting suitable fabrics and colors. Only a solid strategy can make team jerseys wonderful. Before rushing into application, there are techniques and maintenance tips that can keep those patches looking sharp throughout the season.

Understanding details will lead to choosing the perfect stuff and glowing any team’s uniform—let’s explore what you need to know.

Understanding Design Principles of Team

Making player numbers and patches must follow some design principles in the beginning. You need to consider clarity, ensuring that the numbers stand out and are easily readable from a distance.

Font Style: Choose a font that reflects your team’s personality but remains legible and bold enough on the back of players. Patches Mania has done many patches for player uniforms, and most of the time, it is sans-serif style font that often works best.

Colors: Think about color contrast; a dark number on a light background or vice versa enhances visibility.

You must have noticed that when the jerseys of soccer teams match close enough, the management switches any of one team’s colors completely. This also happens for state-level and school tournaments. So, I understand the estimated fixtures, opponents’ teams, and uniforms well. It plays a crucial role in team identity and visibility.

Size: Balance is important, too; ensure your patch size complements the garment without overpowering it. Additionally, keep the overall layout simple and cohesive, integrating any logos or team names seamlessly.

We recommend that players’ numbers on the back center be between 8 and 12 inches, and for the left breast size numbers and patches, sports team garments should be between 3 and 5 inches (on the bigger side).

Material of Customized Numerics for Players

Make sure that the patch should stand out against the fabric. Choosing the correct materials for player identifiers can significantly impact both durability and appearance.

Start with a sturdy fabric like twill or felt, which can withstand wear and tear during games.

Base Material: Find a valid vendor online that has been doing sports patches in the past. Ask them to use materials that should not only be tough but also provide a nice texture.

Next, consider;

Weight of the fabric: a heavier option often holds up better over time. If you’re looking for flexibility, lightweight polyester blends can be a good choice.

Remember, selecting the right combination of materials will help create patches that look great and last season after season.

Application Technique of Patches & Numbers

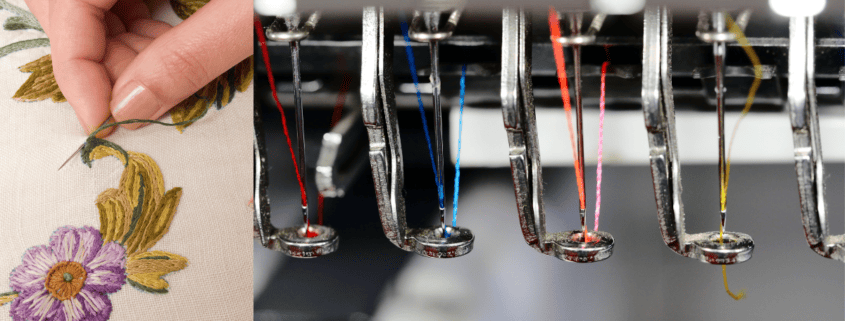

Application procedures of player custom patches include sew-on, iron-on, adhesive, and Velcro hook.

The big numbers on the back of players’ jerseys are mostly heat presses or sew-ons.

A heat-sealed backing can make application easier. You need to iron them onto players’ garments. Plain/No backing offers clean backing; these patches can be stitched only.

How To Apply for Customized Player Numbers on Team Jersey

Start by preheating your iron to the appropriate temperature for the fabric. Position the patches where you’d like them on the uniform, ensuring they’re aligned properly.

Use a pressing cloth to protect the fabric and patches while you press down firmly for about 15-20 seconds. Let the patches cool completely before moving the garment to prevent peeling.

For more details, read my complete guide to iron on patches.

If you’re using adhesive patches, follow the manufacturer’s instructions carefully. Lastly, double-check that all edges are securely attached.

This way, your customized player number patches will look sharp and last throughout the season!

CARE TIPS

Designing custom-sized players’ clothing is not a one-shot job. You have to indulge in many steps to ensure you ultimately get the perfect sporting items.

Here are a few of the caring tips to keep your player numbers and customized patches looking fresh and vibrant.

- Always wash your jerseys inside out to protect the patches from abrasion.

- Use cold water and a gentle cycle to prevent fading.

- Avoid bleach and fabric softeners, as they can damage the player patches.

- When drying, skip the dryer—air drying is best to maintain the patch’s integrity.

- Inspect patches for any signs of wear or peeling.

- If you notice any sign of peeling of player patches, consider reapplying ironing or sewing.

- Store your jerseys in a cool, dry place, away from direct sunlight, to prevent discoloration.

With these simple tips, your patches will stay in top shape throughout the season.

Custom Patches Mania

Custom Patches Mania

Custom Patches Mania

Custom Patches Mania Custom Patches Mania

Custom Patches Mania Custom Patches Mania

Custom Patches Mania

Custom Patches Mania

Custom Patches Mania

Custom Patches Mania

Custom Patches Mania